Designed to convert seawater to drinking water, these seawater desalination systems use high quality membranes and our proven technology to give dependable performance and to comply with WHO Standard for Safe Drinking Water of less than 500 ppm of Total Dissolved Solids.

We offer a full range of both standard and custom engineered Seawater Reverse Osmosis Systems for applications ranging from yachts, cruise ships to municipalities, resorts, military, and various industrial applications.

Understanding Seawater Reverse Osmosis (Swro)

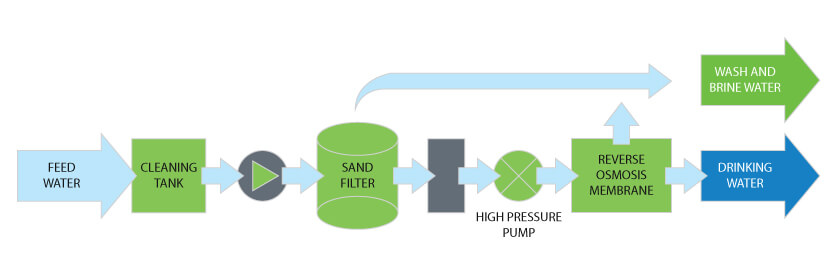

Sea water reverse osmosis is a simple process that involves a high pressure pump, forcing salty water through semi-permeable membrane. Salt, bacteria, colloids and other impurities are rejected by the membrane and only the tiniest water molecules are permitted to pass, leaving you with thousands of gallons of purified water at the other end.

The process begins by passing sea water(feed water) through various pre filters to remove many of the solids and particles from the water. Before the feed water enters the RO membranes, an antiscalant is injected into the feed water and sent through the system. Antiscalant is common chemical options for keeping contaminants from precipitating onto the RO membrane so that they pass safely into the Waste Water Stream. Feed water then goes through a reverse osmosis process, by employing a High Pressure Pumps to the pretreated seawater forcing it through a set of semi-permeable membranes at high pressure . It’s here that the membranes remove the particles the pre filters missed. The membrane lets water flow through it but blocks the salts, so the water beyond the membrane, called the permeate, is desalinated . The concentrated salt water leaves via a pressure control valve. The higher the salt concentration, the more pressure is required to separate the salt. Finally it is sterilized with a UV sterilizer system to kill any remaining bacteria and microbes. The result is clean potable drinking water.

See the diagram below for further understanding:

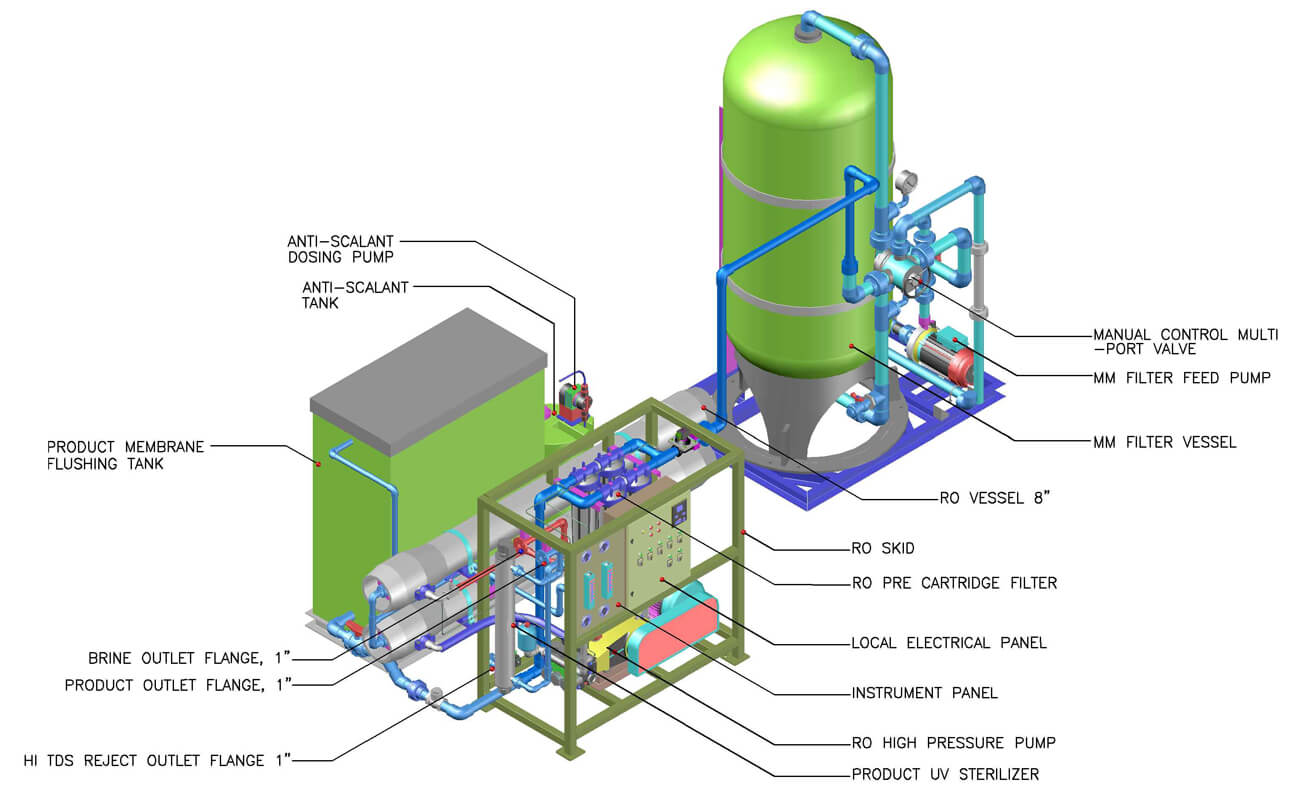

Below is an illustration of an Industrial Sea Water Reverse Osmosis System carrying out the Reverse Osmosis process. The system comes as a complete package, skid mounted with all necessary accessories and controls.

Standard Components Of Seawater Reverse Osmosis System

- Thin Film Composite Seawater Membranes

- FRP Seawater Pressure Vessels

- Prefilter & Housing

- 316 Stainless Steel Pressure Gauges

- 316 Stainless Steel Low and High Pressure Switches

- 316 Stainless Steel Back Pressure Regulator

- Low and High Pressure Safeguards

- Stainless Steel / Nickel Aluminum Bronze High Pressure Pumps

- Pulsation Dampener

- Pressure Relief Valve

- Antiscalant Injection

- Auto Permeate Flush System with Tank, Pump & Controls

- Cleaning Ports

- Auto Operation with Level Controls

- Reset Switch to Restart

- Powder Coated Skid

- Permeate and Concentrate Flowmeters

- Control Panel, with

– Delayed Start-Up of High Pressure Pump

– Low and High Pressure Switch

– RO and Auxiliary Pump Control Relays

– Product Water Quality TDS

– Permeate Dump

– Membrane Permeate Flush at Each Shut-Down

– RO Storage Tank Full and Low

– Pretreatment Lock Out

Optional Components Of Seawater Reverse Osmosis System

- Ultraviolet Sterilizer

- Sodium Bisulfite or Chlorine Injection System

- Differential Pressure Gauge

- Energy Recovery

- Turbidity Meter

- ORP Meter

- Duplex Stainless Steel High Pressure Pump

- Multimedia Filters

- Crating